CPVC Resin Product Details

Product Description

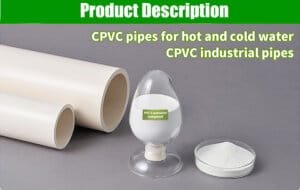

Chlorinated Polyvinyl Chloride (CPVC) resin is a thermoplastic material that offers enhanced heat resistance, chemical stability, and excellent mechanical properties compared to standard PVC. CPVC resin is primarily used in the production of high-temperature resistant piping systems, industrial applications, and chemical processing. With its superior resistance to both high temperatures and harsh chemicals, CPVC is an ideal material for applications requiring reliability under extreme conditions.

Key Features:

- Exceptional high-temperature resistance (up to 90°C continuously, up to 110°C intermittently)

- Superior chemical and corrosion resistance

- High impact resistance

- Enhanced durability and mechanical strength

- Compatible with PVC, PE, and other materials for blending

- Excellent performance in both indoor and outdoor environments

- Flame retardant

Production Process

CPVC resin is manufactured by chlorinating PVC resin, which is then processed to form a high-performance material suitable for various industrial uses. The production process involves several stages:

- Raw Material Selection: The base material, PVC resin, is selected for its initial high performance.

- Chlorination Process: PVC resin undergoes chlorination with chlorine gas in a controlled environment. This increases the chlorine content in the polymer, thereby enhancing its thermal stability and chemical resistance.

- Neutralization & Washing: The chlorinated polymer is neutralized to remove any residual chlorine or by-products. This process is followed by thorough washing to ensure purity.

- Drying & Milling: The resin is dried and milled into fine powder or granules, making it suitable for a variety of manufacturing processes.

- Quality Control & Packaging: Final testing is done to ensure consistency in chlorine content, viscosity, and mechanical properties before packaging the product for shipment.

Product Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Product Name | – | Chlorinated Polyvinyl Chloride (CPVC) Resin |

| CAS No. | – | 9002-86-2 |

| Molecular Formula | – | (C3H3Cl)n |

| Appearance | – | White powder or granules |

| Chlorine Content | ASTM D2084 | 63 – 70% |

| Density | ASTM D792 | 1.4 – 1.5 g/cm³ |

| Tensile Strength | ASTM D638 | 40 – 60 MPa |

| Elongation at Break | ASTM D638 | 50 – 70% |

| Shore Hardness (A) | ASTM D2240 | 80 – 90 |

| Heat Resistance | – | Up to 110°C |

| Processing Methods | – | Extrusion, Injection Molding, Blending |

Note: Values may vary depending on the grade and manufacturer.

Product Applications

CPVC resin is widely used in various industrial and commercial applications due to its outstanding performance in demanding environments. Common applications include:

- Piping Systems: High-temperature pipes for industrial and residential applications, including hot water piping systems.

- Chemical Processing: For manufacturing chemical-resistant pipes, tanks, and fittings in industrial chemical processing environments.

- Plumbing Systems: Used in both residential and commercial hot water pipes.

- Flame Retardant Materials: Used in flame-retardant construction materials, automotive components, and electrical insulation.

- Industrial Coatings: Suitable for protective coatings requiring heat and chemical resistance.

- Specialty Applications: In applications where heat resistance, chemical stability, and impact resistance are critical, such as in power plants and refineries.

Polyvinyl Chloride (CPVC) resin at competitive prices. Contact us today! 🚛📦

Packaging & Transportation

Packaging Details:

- Bag Type: 25 kg woven bags with inner PE lining for small quantities

- Bulk Packaging: 500 kg or 1000 kg jumbo bags are available upon request

- Custom Branding: Available for large-volume orders

Storage & Handling:

- Store in a cool, dry, and well-ventilated area away from direct sunlight.

- Keep away from heat sources and moisture to maintain product quality.

- Handle with care to prevent contamination and mechanical damage.

Shipping Details:

- Delivery Method: By sea, land, or rail, depending on customer requirements.

- Loading Capacity: 20-22 MT per 20′ FCL; 25-27 MT per 40′ HQ container

- Lead Time: 7-15 days after order confirmation

- Port of Loading: Major seaports in China

About Henan Yaros Chemical Co., Ltd.

Henan Yaros Chemical Co., Ltd., founded in 2005 and headquartered in Zhengzhou, Henan Province, specializes in the manufacturing and export of chemical raw materials. With over 18 years of industry experience, we have established a strong reputation for providing high-quality products, competitive pricing, and professional service to customers across Europe, Asia, the Middle East, and beyond.

Our extensive product portfolio includes:

✔ Surfactants & Detergents: SLES, LABSA, AOS, CDEA, CAB

✔ Plastics & Polymers: PVC resin, HDPE, LDPE, LLDPE, PP, PET

✔ Pigments & Colorants: Iron Oxide, Lithopone, Indigo Blue, Sulphur Black

✔ Plasticizers: Dioctyl Phthalate (DOP), Dibutyl Phthalate (DBP), Dioctyl Terephthalate (DOTP), Dioctyl Adipate (DOA), Diisononyl Phthalate (DINP)

✔ Industrial Chemicals: Sodium Hydrosulphite (SHS), Basic Chrome Sulphate (BCS), Sodium Hexametaphosphate (SHMP), Carboxy Methyl Cellulose (CMC), Zinc Oxide, Carbon Black, Sodium Gluconate

✔ Other Specialty Chemicals: Used in detergents, cleaning products, textiles, plastics, petroleum, construction, pharmaceuticals, water treatment, coatings, and more.

We are committed to maintaining the highest quality standards and hold internationally recognized certifications, including ISO 9001:2015, SGS, and FAMI-QS.

🚀 Henan Yaros Chemical Co., Ltd. – Your Reliable Chemical Partner!

Our Certificates

We maintain internationally recognized certifications to ensure product quality, safety, and compliance:

✅ ISO 9001:2015 – Quality Management System Certified

✅ SGS Certification – Third-Party Verified Quality

✅ FAMI-QS Certification – Compliance with Global Standards

Frequently Asked Questions (FAQ)

Q1: What is CPVC resin and how does it differ from regular PVC?

A: CPVC resin (Chlorinated Polyvinyl Chloride) is a modified form of PVC resin with enhanced heat resistance and chemical stability due to the chlorination process. Unlike regular PVC, which is limited to lower temperature applications, CPVC can withstand higher temperatures (up to 110°C) and is more resistant to a wider range of chemicals, making it ideal for high-temperature piping systems, chemical processing, and industrial applications.

Q2: What is the minimum order quantity (MOQ)?

A: Our MOQ is 1 ton, with bulk pricing available for larger orders.

Q3: Can I request a sample before ordering?

A: Yes! We provide free samples, and you only need to cover shipping costs.

Q4: How do you ensure product quality?

A: We follow strict quality control procedures, including raw material inspection, in-process monitoring, and final testing.

Q5: What are the payment terms?

A: We accept T/T, L/C, and Western Union, with negotiable terms for bulk orders.

Q6: How fast is the delivery?

A: Standard delivery time is 7-10 days, depending on order quantity and shipping method.

📩 Still have questions? Contact us today!