Hanwha High-Density Polyethylene (HDPE) Product Details

High-Density Polyethylene (HDPE) Product Description

High-Density Polyethylene (HDPE) is a versatile thermoplastic polymer known for its high strength-to-density ratio, excellent impact resistance, and chemical stability. It is widely used across various industries due to its durability, lightweight nature, and resistance to moisture and many chemicals. HDPE is commonly utilized in applications such as packaging, piping, geomembranes, and plastic lumber.

Production Process

HDPE is produced through the polymerization of ethylene monomers. The two primary methods are:

Slurry Polymerization (Ziegler-Natta Process): Utilizes catalysts to produce HDPE with minimal branching, resulting in high-density material.

Gas Phase Polymerization: Employs a fluidized bed reactor to produce HDPE under controlled temperature and pressure conditions.

The choice of process affects the polymer’s properties, allowing customization for specific applications.

Product Specifications

HDPE resins are available in various grades, each tailored for specific applications. Below is a table summarizing typical properties:

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D792 | 0.940 – 0.976 g/cm³ |

| Melt Index (190°C/2.16 kg) | ASTM D1238 | 0.35 g/10 min |

| Tensile Strength at Yield | ASTM D638 | 3,900 – 4,700 psi (27 – 32 MPa) |

| Flexural Modulus | ASTM D790 | 174,000 – 237,000 psi (1,200 – 1,635 MPa) |

| Elongation at Break | ASTM D638 | >600% |

| Vicat Softening Temperature | ASTM D1525 | 126°C (259°F) |

| Environmental Stress Crack Resistance (ESCR) | ASTM D1693 | 50 hours |

Note: Values may vary depending on the specific grade and manufacturer.

Applications

HDPE’s unique properties make it suitable for a wide range of applications, including:

Packaging: Bottles, containers, and plastic bags due to its strength and food-safe characteristics.

Pipes and Fittings: Used in water and gas distribution systems for its durability and corrosion resistance.

Construction Materials: Geomembranes, plastic lumber, and corrosion-resistant materials.

Consumer Goods: Household items like cutting boards, toys, and storage sheds.

Agriculture: Irrigation pipes and agricultural films.

Automotive: Fuel tanks and other components requiring chemical resistance.

Packaging and Transportation

Packaging: HDPE resins are typically supplied in pellet form, packaged in 25 kg bags or bulk containers, depending on customer requirements.

Transportation: Due to its lightweight nature, HDPE is cost-effective to transport. Products should be handled to prevent damage, and storage conditions should protect against UV exposure to maintain material integrity.

About Henan Yaros Chemical Co., Ltd.

Henan Yaros Chemical Co., Ltd., founded in 2005 and headquartered in Zhengzhou, Henan Province, specializes in the manufacturing and export of chemical raw materials. With over 18 years of industry experience, we have established a strong reputation for providing high-quality products, competitive pricing, and professional service to customers across Europe, Asia, the Middle East, and beyond.

Our extensive product portfolio includes:

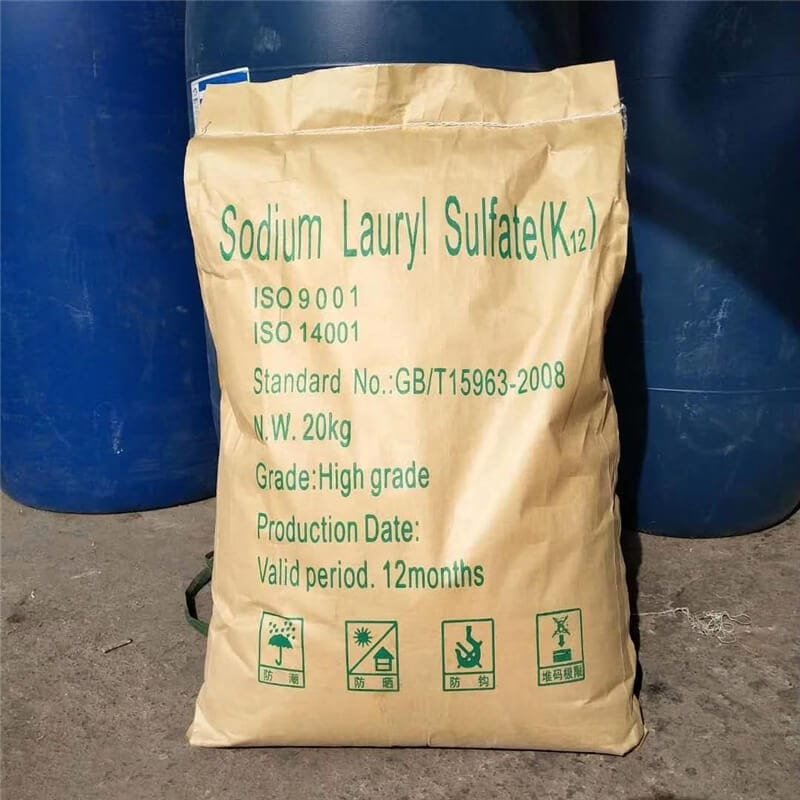

✔ Surfactants & Detergents: SLES, LABSA, AOS, CDEA, CAB

✔ Plastics & Polymers: PVC resin, HDPE, LDPE, LLDPE, PP, PET

✔ Pigments & Colorants: Iron Oxide, Lithopone, Indigo Blue, Sulphur Black

✔ Plasticizers: Dioctyl Phthalate (DOP), Dibutyl Phthalate (DBP), Dioctyl Terephthalate (DOTP), Dioctyl Adipate (DOA), Diisononyl Phthalate (DINP)

✔ Industrial Chemicals: Sodium Hydrosulphite (SHS), Basic Chrome Sulphate (BCS), Sodium Hexametaphosphate (SHMP), Carboxy Methyl Cellulose (CMC), Zinc Oxide, Carbon Black, Sodium Gluconate

✔ Other Specialty Chemicals: Used in detergents, cleaning products, textiles, plastics, petroleum, construction, pharmaceuticals, water treatment, coatings, and more.

We are committed to maintaining the highest quality standards and hold internationally recognized certifications, including ISO 9001:2015, SGS, and FAMI-QS.

🚀 Henan Yaros Chemical Co., Ltd. – Your Reliable Chemical Partner!

Our Certificates

We maintain internationally recognized certifications to ensure product quality, safety, and compliance:

✅ ISO 9001:2015 – Quality Management System Certified

✅ SGS Certification – Third-Party Verified Quality

✅ FAMI-QS Certification – Compliance with Global Standards

Frequently Asked Questions (FAQ)

Q1: What is the difference between HDPE Injection, Blow Molding, and Film grades?

A: HDPE Injection grade is designed for producing rigid plastic parts and containers, Blow Molding grade is ideal for manufacturing bottles and hollow products, while Film grade is used for creating thin, flexible plastic films and packaging materials.

Q2: What is the minimum order quantity (MOQ)?

A: Our MOQ is 1 ton, with bulk pricing available for larger orders.

Q3: Can I request a sample before ordering?

A: Yes! We provide free samples, and you only need to cover shipping costs.

Q4: How do you ensure product quality?

A: We follow strict quality control procedures, including raw material inspection, in-process monitoring, and final testing.

Q5: What are the payment terms?

A: We accept T/T, L/C, and Western Union, with negotiable terms for bulk orders.

Q6: How fast is the delivery?

A: Standard delivery time is 7-10 days, depending on order quantity and shipping method.

📩 Still have questions? Contact us today!